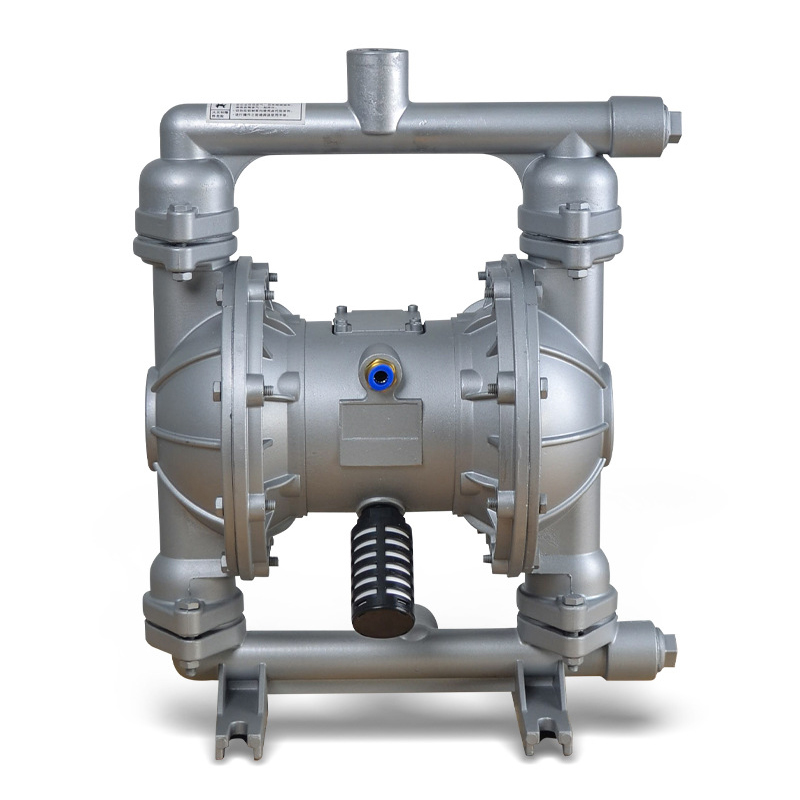

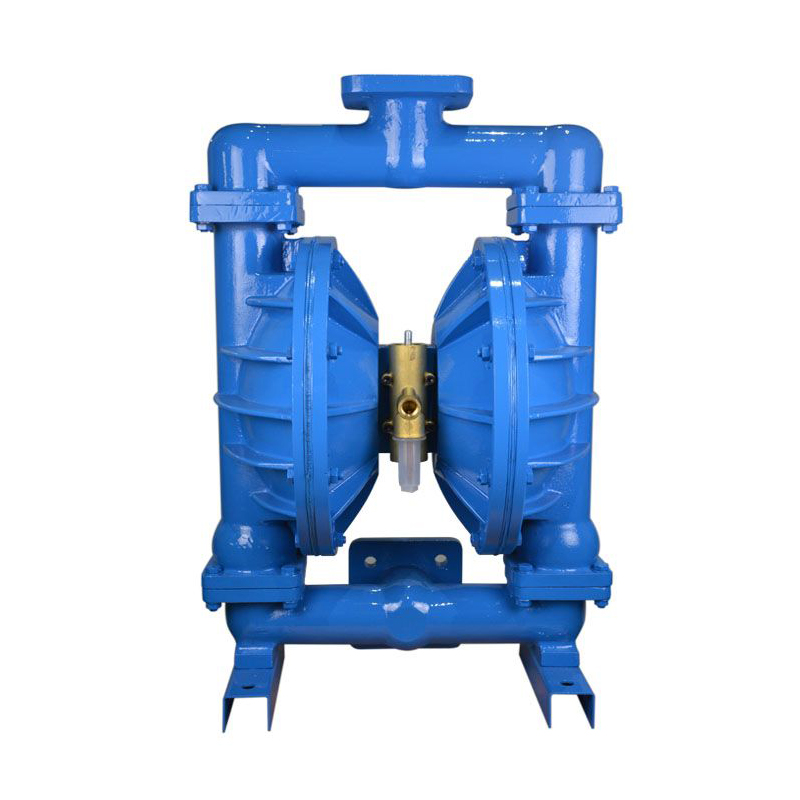

Plastic Chemical Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

The features of a Plastic Chemical Diaphragm Pump may include:

1. Corrosion Resistance: Designed to handle chemicals, these pumps are typically constructed from high-performance plastic materials, offering excellent corrosion resistance. They can safely and reliably transport various corrosive media such as acids, alkalis, solvents, etc.

2. Energy Efficiency and Environmental Friendliness: Compared to traditional pump technologies, plastic chemical diaphragm pumps often utilize pneumatic drives, eliminating the need for electricity and thus promoting energy efficiency and environmental friendliness. Additionally, their sealed design effectively prevents leaks, reducing chemical volatilization and environmental pollution.

3. High Reliability: These pumps feature a simple yet stable structure, requiring no additional lubrication, thus reducing maintenance costs and downtime. With a dual-diaphragm design, they ensure the stability and safety of fluid transportation. Even if one side fails, the other side can continue working, ensuring continuous production processes.

4. Wide Applicability: Due to their superior material selection and structural design, plastic chemical diaphragm pumps are suitable for various industries and applications, including chemical, petroleum, pharmaceutical, food processing, etc. They fulfill the requirements of different media transportation needs.

Plastic Chemical Diaphragm Pump working principle

In each of the two symmetrical working chambers of the diaphragm pump, there is a resilient diaphragm 6 installed. A connecting rod links the two diaphragms together, and compressed air enters the pump through the air inlet 1 to actuate the diaphragms in the two working chambers, driving the synchronized movement of the two diaphragms connected by the connecting rod.

Meanwhile, gas in the other working chamber is discharged from behind the diaphragm to the outside of the pump. Once the stroke ends, the valve mechanism automatically introduces compressed air into the other working chamber, driving the diaphragms to move in the opposite direction, thus creating synchronous reciprocating motion of the two diaphragms. Two one-way ball valves 4 are installed in each working chamber. The reciprocating motion of the diaphragms causes changes in the volume of the working chambers, forcing the two one-way ball valves to alternately open and close, thus continuously suctioning and discharging the liquid.

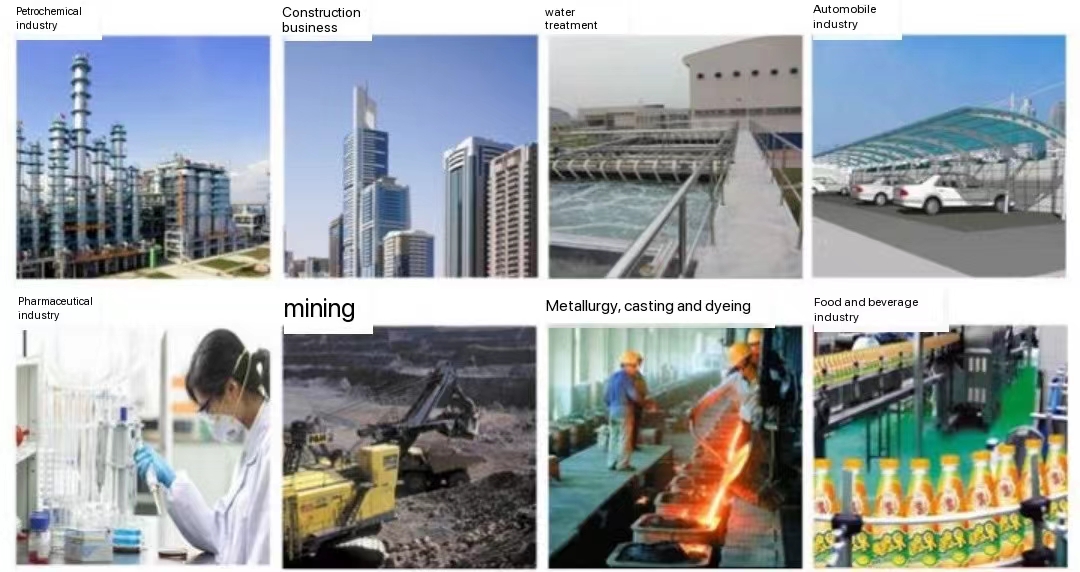

Plastic Chemical Diaphragm Pump application

Plastic Chemical Diaphragm Pump finds its application across a diverse range of industries owing to its versatility, reliability, and chemical resistance. This pump is specifically designed to handle corrosive and abrasive fluids, making it suitable for various sectors where such substances are involved.

In chemical processing plants, these pumps are utilized for transferring acids, alkalis, solvents, and other aggressive chemicals safely and efficiently. They are also extensively used in water treatment facilities for dosing chemicals like chlorine and fluoride. Additionally, in the automotive industry, these pumps play a crucial role in transferring fluids such as oils, coolants, and hydraulic fluids during manufacturing processes.

Laboratories and research facilities benefit from their precise metering capabilities, ensuring accurate dispensing of reagents and samples. Moreover, plastic chemical diaphragm pumps find applications in the pharmaceutical industry for handling delicate and hazardous substances with stringent hygiene requirements.

The food and beverage industry also utilizes these pumps for transferring flavorings, additives, and cleaning agents. Their robust construction, along with the ability to handle a wide range of chemicals, makes them indispensable in various industrial processes where safety, reliability, and chemical compatibility are paramount concerns.