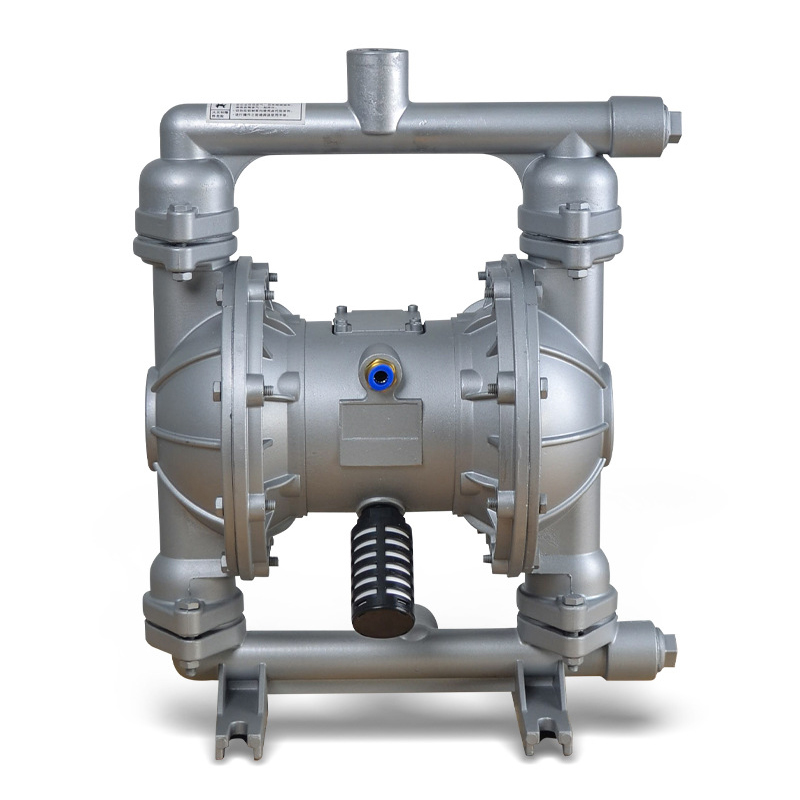

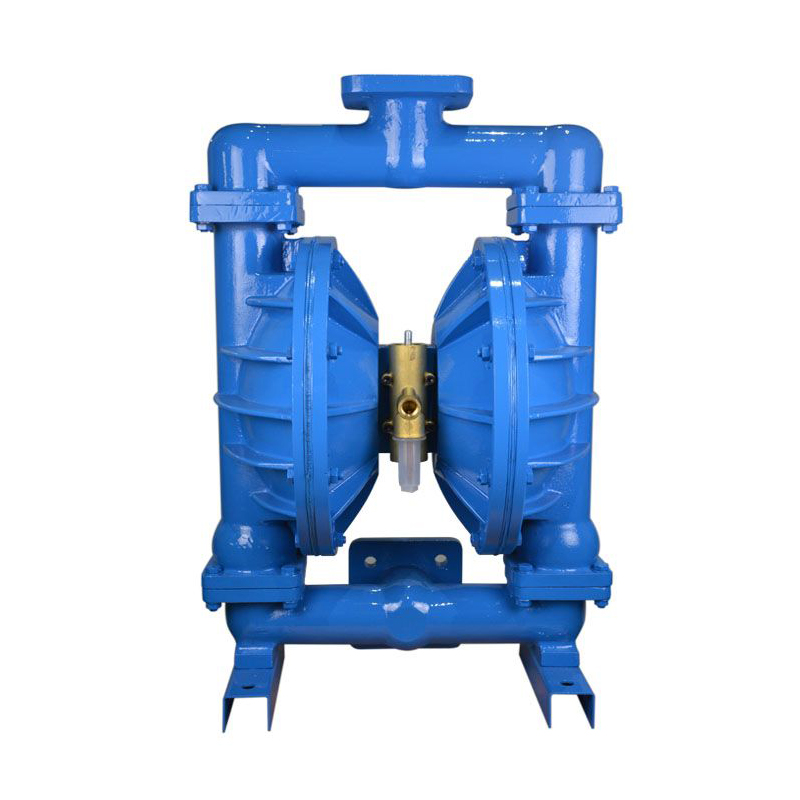

Acid Resistance Airpowered Transfer Pump

- Gaotian

- Shanghai

- 15days

- 1500

Acid Resistance Airpowered Transfer Pump technical parameters

Maximum particle diameter: 6 mm

● Maximum flow rate: 587 L/min

● Maximum head: 84 m

● Maximum air supply pressure: 8.4 bar

● Self-priming head: 0-8 m

● Inlet/outlet port: 2 in

Materials

● Pump body: Polypropylene, Polyoxymethylene (POM), PVDF, PTFE

● Diaphragm: Santoprene rubber, Polyether rubber, Fluororubber, PTFE, EPDM, Nitrile rubber

● Valve ball: PTFE, Stainless steel, Santoprene rubber, Polyether rubber, Fluororubber, Ceramic

● Valve seat: PTFE, Santoprene rubber, Polyether rubber, Fluororubber, Polypropylene

Acid Resistance Airpowered Transfer Pump features

Explosion-proof, zero leakage, simple operation

Can run dry. Self-priming, no complex control

Can handle high viscosity fluids

Can handle large particles in the fluid

Diverse materials, no rotating parts, suitable for corrosive environments

Adjust pump head by changing air supply pressure

Adjust flow rate by changing air supply volume

Overload operation, pump will automatically shut down

No mechanical seals, easy maintenance, low cost

Modular design, no fragmentation, easy to disassemble and repair

The Four Working Principles of Acid Resistance Airpowered Transfer Pump

1. When the plunger rises to the upstroke, the selection valve opens again, and compressed air drives the plunger to discharge oil.

2. In the absence of load, the above action is repeated at a high-speed frequency of approximately 2000 strokes per minute until the air pressure and oil pressure stabilize. When both pressures reach a constant level, the pump's cyclic action will automatically stop. If the oil pressure circuit pressure unexpectedly drops, as long as compressed air is continuously supplied, the pump will automatically operate until the oil pressure returns to a constant level.

3. Compressed air enters through the filter screen, driving the selection valve to descend, and then the gas enters the cylinder through the passage to drive the piston down. The plunger connected to the piston moves simultaneously with the piston, and the plunger presses the oil in the chamber out through the check valve.

4. When the plunger descends to the downstroke, the selection valve closes, preventing compressed air from entering the cylinder. Then, the spring inside the cylinder overcomes the pressure of the compressed air and drives the piston to rise. The plunger also rises accordingly, and at this time, the intake check valve opens to draw oil into the chamber, and the gas is discharged from the silencer through the passage.

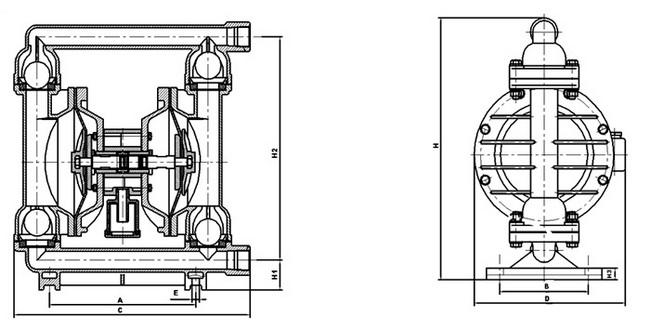

Acid Resistance Airpowered Transfer Pump section drawing