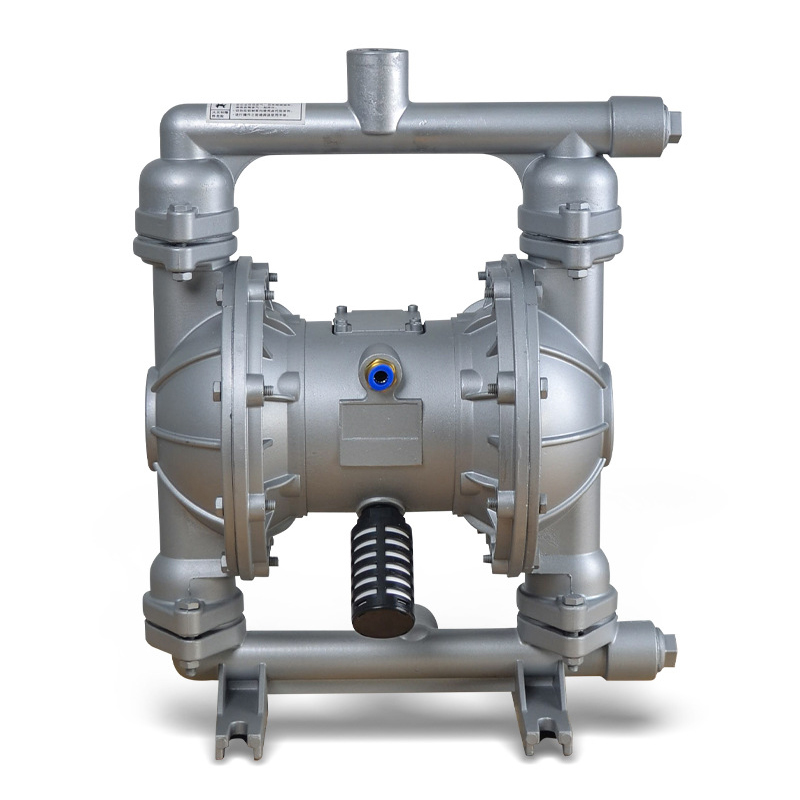

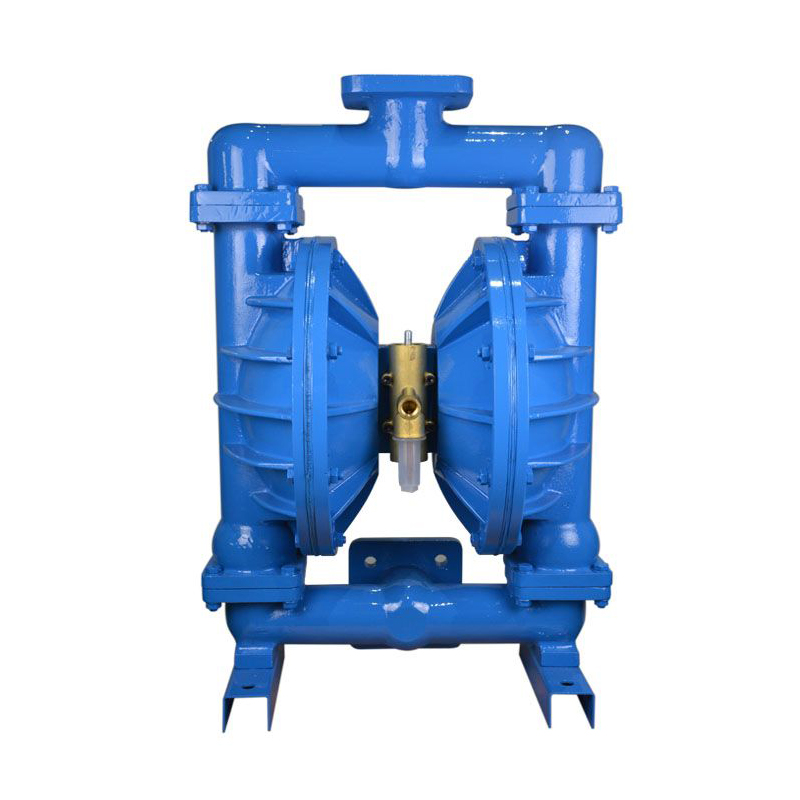

Air Operated Double Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

Product Features of Air Operated Double Diaphragm Pump:

● Air-driven diaphragm design allows for handling liquids with solid particles and high viscosity.

● Air-driven operation is suitable for use in high-risk environments.

● Anti-stalling air valve reduces pump downtime, freezing, and lubricant use issues.

● When using Teflon diaphragms, the flow rate decreases by 20%, and the self-priming height decreases to 10 feet (dry) or 20 feet (wet).

Pneumatic diaphragm pumps are a new type of conveying machinery powered by compressed air, capable of pumping out various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids.

Working Principle of Pneumatic Diaphragm Pump

In the two symmetrical working chambers of the pneumatic pump, each is equipped with a flexible diaphragm. The connecting rod joins the two diaphragms together. Compressed air enters the distribution valve from the pump's air inlet, pushing the diaphragms in the two working chambers and driving the synchronously moving diaphragms connected by the connecting rod. At the same time, the gas in the other working chamber is discharged from behind the diaphragm to the outside of the pump. Once it reaches the end of the stroke, the distribution mechanism automatically introduces compressed air into the other working chamber, pushing the diaphragm in the opposite direction, thus forming the synchronous reciprocating motion of the two diaphragms. Two check valves are installed in each working chamber. The reciprocating motion of the diaphragm causes changes in the volume of the working chamber, forcing the two check valves to alternately open and close, thus continuously sucking in and discharging the liquid.

Characteristics of Pneumatic Diaphragm Pump

Spacious flow, good passability, allowing for a maximum particle diameter of up to 10 millimeters. When pumping slurry and impurities, the wear on the pump is minimal.

Pneumatic diaphragm pumps do not require priming, with a suction lift of up to 5 meters, a head up to 70 meters, and an outlet pressure of ≥7 bar.

Pneumatic diaphragm pumps have no rotating parts or shaft seals. The diaphragm separates the pumped medium from the moving parts and working medium of the pump, preventing the pumped medium from leaking out. Therefore, when handling toxic, volatile, or corrosive media, it will not cause environmental pollution or harm to personal safety.

The head and flow rate can be adjusted steplessly through the opening of the air valve (pressure adjustment between 1-7 bar).

Can work submerged in the medium.

It does not require electricity, making it safe and reliable for use in flammable and explosive environments.

Pneumatic diaphragm pumps have a simple structure and few vulnerable parts. The pump has a simple structure, making installation and maintenance convenient. The medium being pumped does not come into contact with the distribution valve, connecting rod, or other moving parts, unlike other types of pumps where the performance gradually decreases due to wear of components such as rotors, pistons, gears, or blades.

Convenient to use, reliable in operation. Starting and stopping only requires simple opening and closing of the gas valve. Even if there is a long period of no medium running or sudden shutdown due to an accident, the pump will not be damaged. Once overloaded, the pump will automatically shut down, providing self-protection. When the load returns to normal, it will automatically restart and operate.

Pneumatic diaphragm pumps do not require oil lubrication, and even when running without load, it has no impact on the pump. This is a major feature of this pump.

Can handle viscous liquids (with a viscosity below 10,000 centipoise).

Air Operated Double Diaphragm Pump applicable industries

Ceramic and Electronics Industry: glazes, feldspar, slurries, etc.

Paint Industry: pigments, varnishes, solvents, paints, etc.

Pharmaceutical Industry: aspirin, sugar, vitamins, etc.

Printing Industry: printing inks, pigments, solvents, etc.

Food Industry: flour, rice flour, starch, powdered milk, etc.

Paper Industry: paper coating, fibers, pulp, wood chips.

Grinding Industry: chemicals, sand, tungsten, carbides, grinding sands.

Chemical Industry: insecticides, chemicals, solvents, catalysts, etc.

Brewery Industry: barley, yeast, hops.

Pollution Control Industry: separating foreign matter from copper wires, stains, etc.

Pharmaceutical Industry: aspirin, sugar, vitamins, etc.

Rubber and Plastic Industry: various chemicals, PVC granules, etc.

Canning and Food Packaging Factories: seafood, lima beans, fruits, blood, etc.

Firefighting Industry: fire sprinkler design, etc.

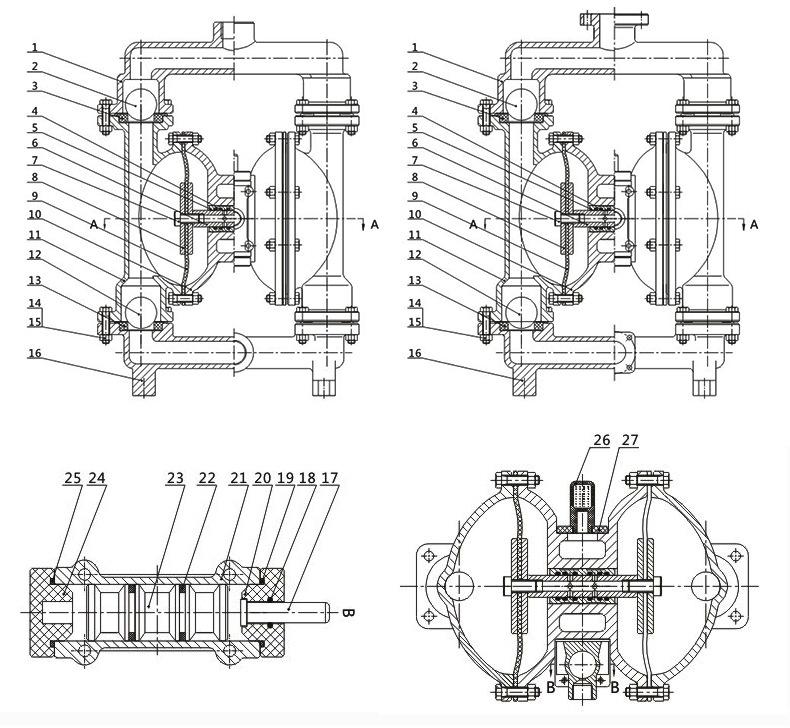

Air Operated Double Diaphragm Pump section drawing

1. Outlet Pipe

2. ball

3. Ball Seat

4.Copper Sleeve O-ring

5. Copper Sets

6.Rod Axis

6. With Steam Valve

7.Department Hex Bolts

8. Inner/Outer Plate

9. Diaphragm

10. Intermediate

11. Column

12.Ball

13.Ball Seat

14.Nuts

15.Department Hex Bolts

16.Inlet Tube

17.Thimble

18.Door Cover O-ring

19. Seal

20.Door Cover

21.With Steam Valve

22.Piston O-ring

23.Pistons

24.Next Door Cover

25.Seal

26.Muffler

27.Cover