Pneumatic Powder Pump

- Gaotian

- Shanghai

- 15days

- 1500

The pneumatic powder pump boasts numerous advantages that make it a preferred choice for fluid transfer operations. Its ability to handle corrosive chemicals, volatile solvents, viscous fluids, and shear-sensitive substances with ease ensures versatility in various industrial settings. Additionally, its capability to transfer dirty water, abrasive slurry, smaller solids, creams, gels, and oils highlights its adaptability across diverse applications. Furthermore, its pneumatic operation enhances safety and efficiency, making it suitable for industries like chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. With reliability and versatility as its key strengths, the pneumatic powder pump stands out as a dependable solution for fluid transfer needs in numerous industrial sectors.

Pneumatic Powder Pump description

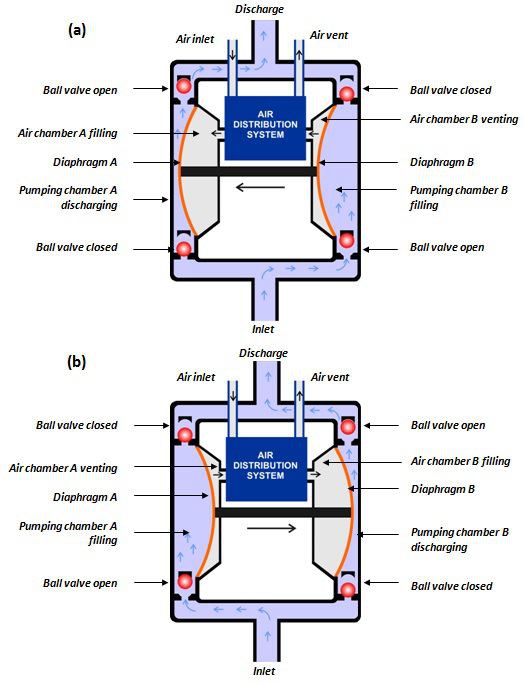

The pneumatic powder pump, also known as a double diaphragm pump, operates by utilizing the reciprocating back-and-forth motion of two flexible diaphragms mounted on a shared shaft to move fluid. This innovative pump design, depicted in Figure 1, offers numerous advantages and is widely used across various industries.

The mechanism of a pneumatic powder pump is based on the oscillating movement of the diaphragms, which are driven by compressed air. Unlike direct drive diaphragm pumps, the pneumatic powder pump employs a sophisticated air distribution system that directs compressed air alternately to two air chambers situated on opposite sides of the diaphragms. This process creates a synchronized movement of the diaphragms, resulting in the efficient transfer of fluids.

One of the key features of the pneumatic powder pump is its versatility and adaptability. This pump can handle a wide range of fluids, including viscous and abrasive substances, making it suitable for diverse applications in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. Its ability to effectively handle challenging fluids sets it apart as a reliable and efficient pumping solution.

Furthermore, the pneumatic powder pump offers inherent safety benefits. By utilizing compressed air as the driving force, it eliminates the need for electrical power near the fluid being pumped, reducing the risk of sparks and potential hazards in environments where flammable or explosive materials are present. This makes it a preferred choice for applications requiring adherence to stringent safety protocols.

The design of the pneumatic powder pump also ensures minimal pulsation and smooth fluid transfer, contributing to improved process stability and product quality. Additionally, its robust construction and minimal moving parts result in reduced maintenance requirements and increased durability, providing long-term cost savings and reliability.

In summary, the pneumatic powder pump, with its unique double diaphragm design and air-driven operation, offers a safe, versatile, and efficient solution for fluid transfer in a wide range of industrial applications. Its ability to handle challenging fluids, minimize pulsation, and ensure operational safety makes it a valuable asset for various industries seeking reliable and high-performance pumping solutions.

Pneumatic Powder Pump application

The pneumatic powder pump is well-suited for a diverse range of applications due to its ability to handle various fluids and substances. Its application scope includes the transfer of corrosive chemicals, volatile solvents, viscous and sticky fluids, shear-sensitive foodstuffs and pharmaceutical products, as well as dirty water, abrasive slurry, smaller solids, creams, gels, and oils. This versatility makes it an ideal pumping solution for industries such as chemical processing, pharmaceuticals, food and beverage, wastewater treatment, and many others. The pump's ability to efficiently and safely transfer such a wide array of substances showcases its adaptability and reliability across different industrial settings, making it a valuable asset for fluid transfer operations.

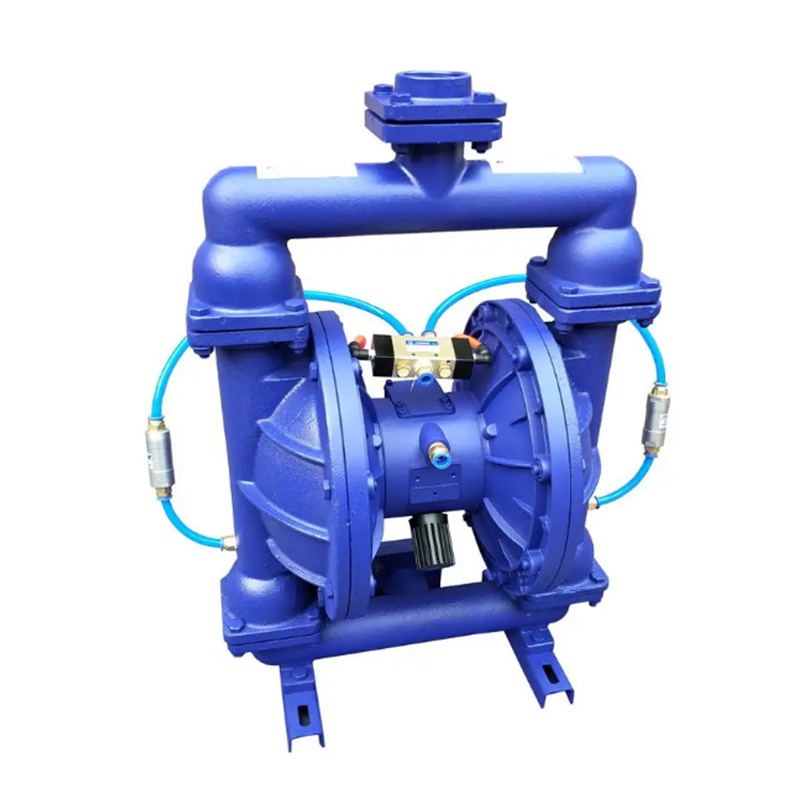

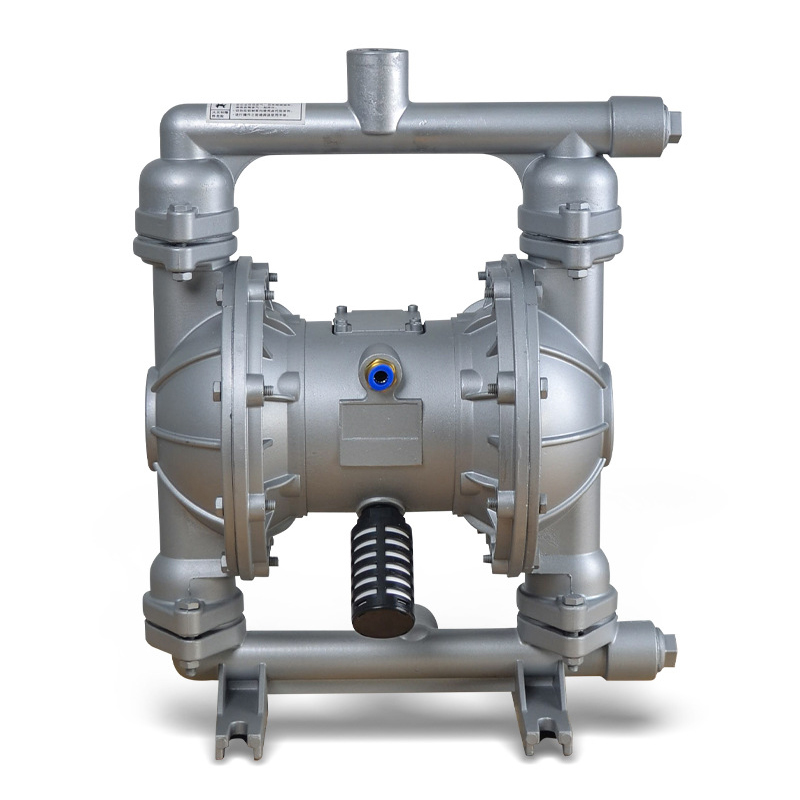

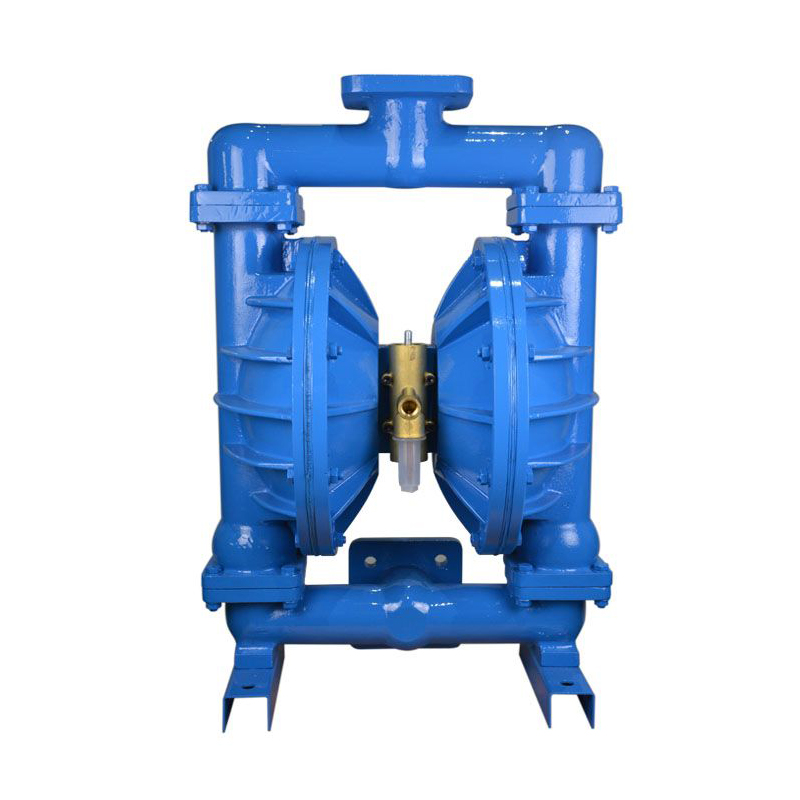

Pneumatic Powder Pump section drawing