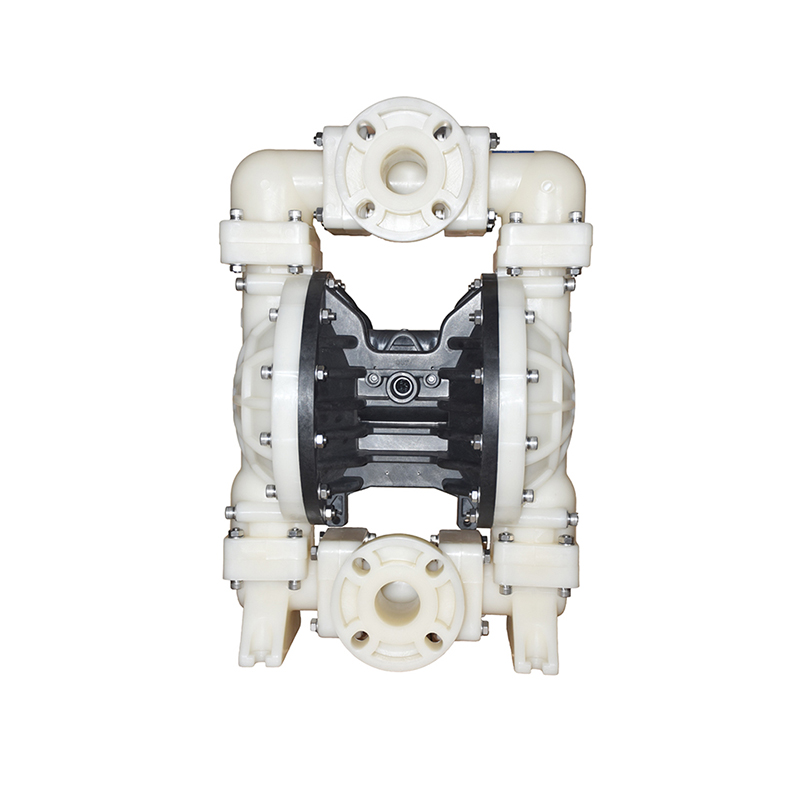

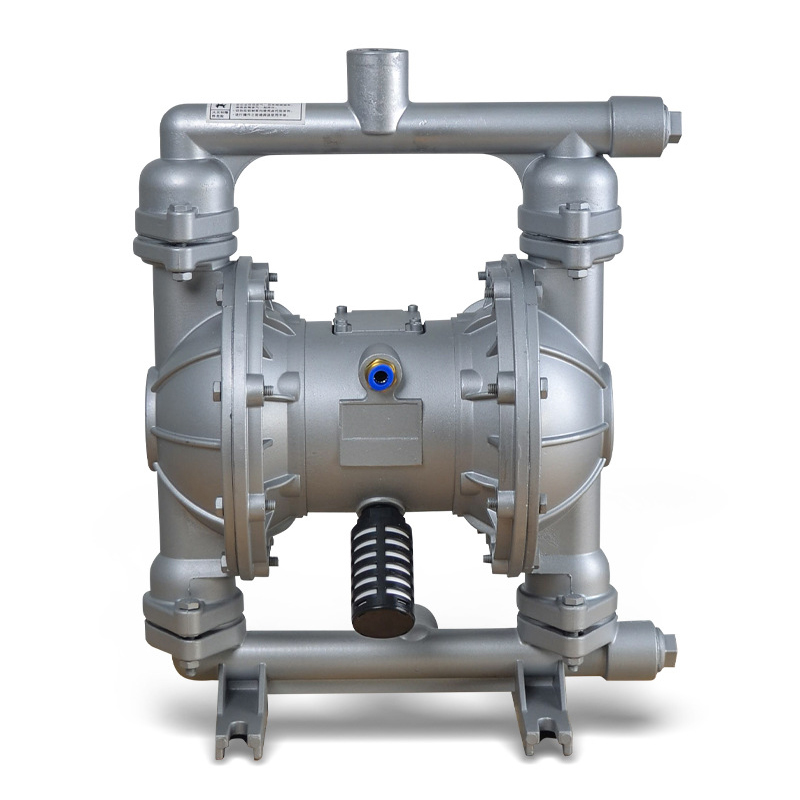

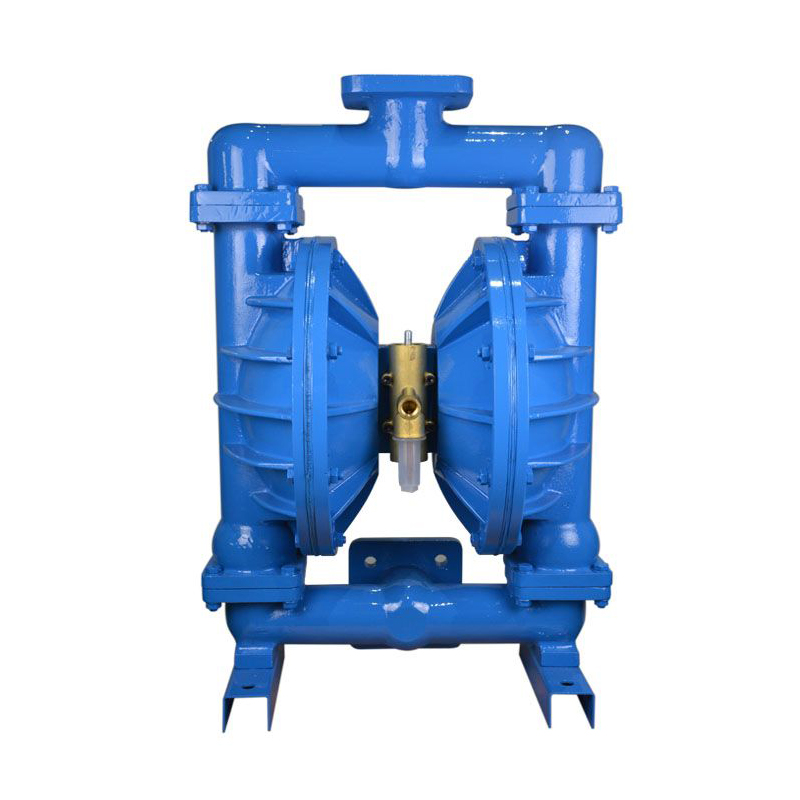

QBK All Plastic Diaphragm Pump

- Gaotian

- Shanghai

- 15days

- 1500

The QBK diaphragm air pump has eight common specifications with diameters of: 10mm (3/8"), 015mm (1/2"), 025mm (1"), 040mm (1/2"), 50mm (2"), 65mm (2 1/2"), 80mm (3"), 100mm (4"). It comes in three materials: aluminum alloy, cast iron, stainless steel. Diaphragm pumps are equipped with different diaphragm materials including nitrile rubber, chloroprene rubber, fluorine rubber, and polytetrafluoroethylene, to meet the needs of different users according to different liquid media.

Since its inception, this pump has been adopted by many units in petroleum, chemical, electronic, ceramic, and textile systems, placed in various special occasions to pump various media that conventional pumps cannot handle, and has achieved satisfactory results.

All Plastic Diaphragm Pump Main Applications

1. Pumping peanut butter, pickles, mashed potatoes, sausages, apple puree, jam, chocolate, etc.;

2. Pumping paints, gums, pigments, etc.;

3. All types of adhesives and glue can be pumped;

4. Various types of roofing tiles, ceramics, brickworks, and ceramic glazes;

5. After drilling oil wells, pumping sediments and grouting;

6. Pumping various emulsions and fillers;

7. Pumping various sewage;

8. Using pumps to pump sewage from tankers and barges during tank cleaning;

9. Beer hops and fermenting yeast slurry, syrup, molasses;

10. Pumping water from mines, tunnels, ore dressing, and water accumulated in slag. Pumping cement grout and mortar;

11. Various rubber latex;

12. Various abrasives, corrosives, petroleum and mud, cleaning grease and general containers;

13. Various highly toxic, flammable, and volatile liquids;

14. Various strong acids, alkalis, and corrosive liquids;

15. Various high-temperature liquids resistant up to 150°C;

16. Used as a primary pressure device for various solid-liquid separation equipment.

All Plastic Diaphragm Pump Working Principle

In the two symmetrical working chambers of the pump, each is equipped with a flexible diaphragm. A connecting rod connects the two diaphragms together. Compressed air enters the valve after the intake joint of the pump, pushing the diaphragms in the two working chambers and driving the two diaphragms connected by the connecting rod to move synchronously. At the same time, the gas in the other working chamber is discharged from the back of its diaphragm. Once reaching the end of the stroke, the distribution mechanism automatically introduces compressed air into the other working chamber, pushing the diaphragm to move in the opposite direction, thus forming the synchronous reciprocating motion of the two diaphragms. Two one-way ball valves are installed in each working chamber. The reciprocating motion of the diaphragm causes changes in the volume of the working chamber, forcing the two one-way ball valves to alternately open and close, thereby continuously sucking in and discharging the liquid.

All Plastic Diaphragm Pump Performance Characteristics

The fluorine-lined pneumatic diaphragm pump can not only pump flowing liquids but also transport some difficult-to-flow media. It has many advantages of conveying machinery such as self-priming pump, submersible pump, shielded pump, slurry pump, and impurity pump.

1. No need for water filling, suction lift up to 7m, head up to 50m, outlet pressure ≥ 6kgf/cm2;

2. Spacious flow, good passability, allowing large particles to pass through. When pumping slurry and impurities with a diameter of up to 10mm, the pump wears very little;

3. Head and flow can be continuously adjusted through the opening of the air valve (air pressure adjustment between 7kgf/cm2);

4. The pump has no rotating parts, no shaft seals, and the diaphragm completely separates the pumped medium from the moving parts and working medium of the pump. The conveyed medium will not leak outward, so when pumping toxic, volatile, or corrosive media, it will not cause environmental pollution or harm human safety;

5. No need for electricity, safe and reliable in flammable and explosive environments;

6. Can work submerged in the medium;

7. Convenient to use, reliable in operation. Starting and stopping only require simply opening and closing the gas valve. Even if there is no medium running for a long time or sudden shutdown due to accidents, the pump will not be damaged. Once overloaded, the pump will automatically stop, with self-protection performance. When the load returns to normal, it can automatically start running again;

8. Simple structure, few vulnerable parts. The pump has a simple structure, easy installation, and maintenance. The medium pumped by the pump does not come into contact with the distribution valve, connecting rod, and other moving parts. Unlike other types of pumps, the performance gradually decreases due to the wear of components such as rotors, pistons, gears, and blades;

9. Can transport viscous liquids (viscosity below 10,000 centipoise);

10. This pump does not require oil lubrication, and even if it idles, it has no effect on the pump. This is a major feature of this pump.

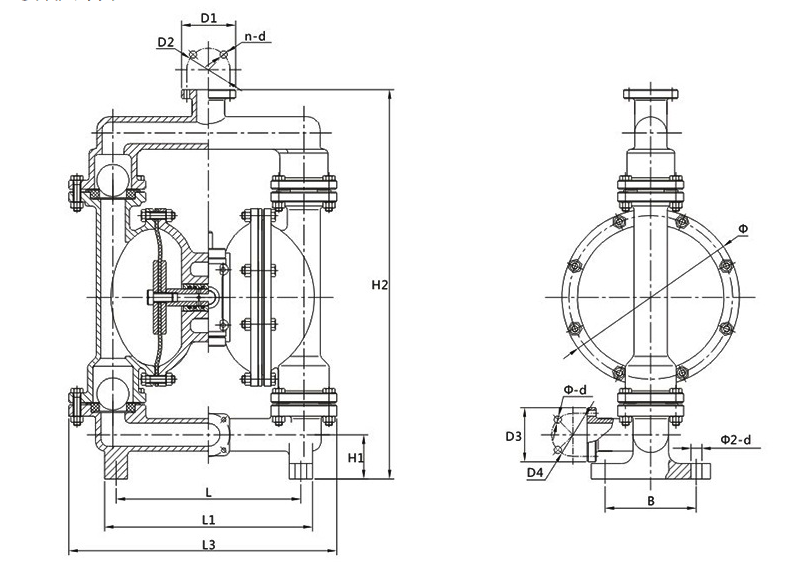

All Plastic Diaphragm Pump section drawing