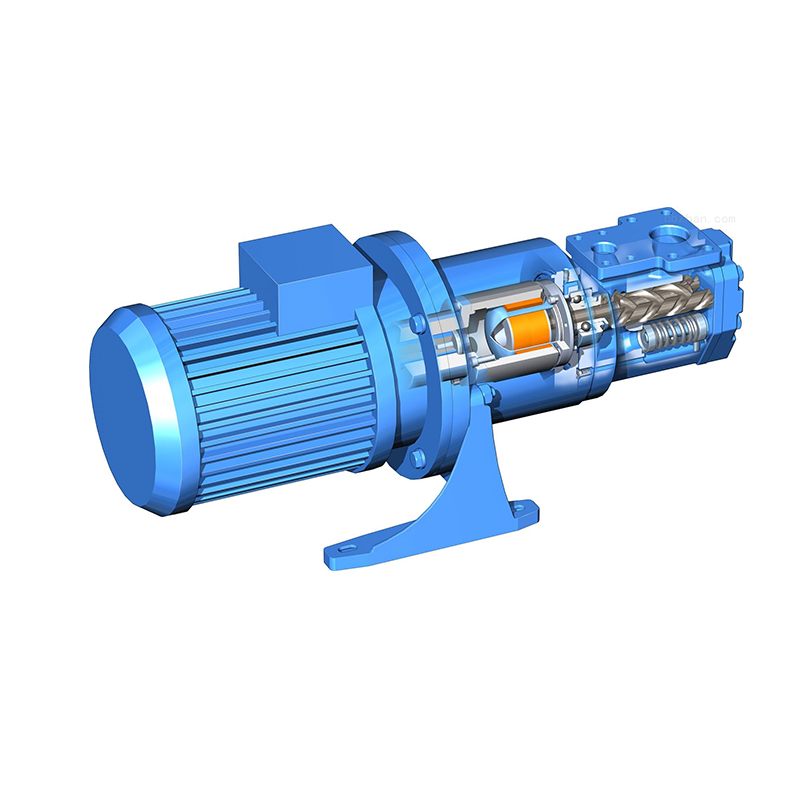

Mono Screw Pump Manufacturers

- Gaotian

- Shanghai

- 15days

- 1500

Mono Screw Pump Manufacturers Characteristics:

Wide range of conveyance: It can effectively transport materials with solids content up to 60% and viscosity as high as 1,000,000 CPS.

Low mechanical vibration and noise: There is no stirring, shearing, turbulence, or agitation of materials during operation.

Strong self-priming capability: The suction lift can reach up to 8.5 meters (28 feet).

Special structure composed of a rigid rotor and an elastic stator enables it to transport materials containing solid particles.

The maximum temperature of the conveyed material can reach up to 120 degrees Celsius, with a maximum flow rate of 260m3/h. The pressure can reach 9.6 MPa.

The flow rate is linearly related to the speed, making it convenient to control the flow rate by adjusting the speed. It is commonly used as a metering pump.

Mono Screw Pump Working Principle

The screw pump operates based on the principle of intermeshing volume displacement. Its main components consist of an eccentric screw (rotor) and a fixed liner (stator). Due to the unique geometrical shapes of these two components, they form separate sealed chambers, through which the medium flows uniformly in an axial direction. This results in low internal flow velocity, constant volume, and stable pressure, thereby avoiding turbulence and agitation.

The output pressure of each stage of the pump is 0.6 MPa with a head of 60m (for clear water), and it typically has a self-priming height of around 6m. It is suitable for conveying media with temperatures below 80°C (special requirements can reach up to 150°C). The stator is made of various elastic materials, enabling this pump to handle high viscosity fluids, as well as media containing hard suspended particles or fibers, which conventional pumps may not be able to handle. Its flow rate is proportional to the speed.

The transmission can be achieved directly via a coupling, making this pump have few components, a compact structure, small size, easy maintenance, and simple assembly and disassembly of the rotor and stator, which are the vulnerable parts of this pump due to its simple structure.

Introduction to the Mono Screw Pump

Single screw pumps, also known as progressive cavity pumps, are versatile pumping devices widely utilized across various industries for their efficiency, reliability, and adaptability to different media. Their unique design and operating principles make them suitable for a diverse range of applications. In this article, we will explore the industries where single screw pumps find significant utility.

Oil and Gas Industry

In the oil and gas sector, single screw pumps play a crucial role in various operations, including crude oil transportation, drilling mud transfer, and offshore platform applications. These pumps excel in handling viscous fluids with high solid content, making them ideal for conveying heavy crude oil, drilling mud, and other challenging substances encountered in exploration and production processes. Additionally, their ability to provide consistent flow and pressure makes them valuable for offshore installations and remote locations.

Wastewater Treatment

Single screw pumps are widely employed in wastewater treatment plants for pumping sludge, sewage, and various types of effluents. Their ability to handle abrasive and viscous fluids, combined with gentle pumping action, makes them suitable for transferring wastewater with suspended solids, fibrous materials, and abrasive particles. These pumps contribute to the efficient processing and treatment of wastewater, ensuring environmental compliance and public health protection.

Food and Beverage Industry

In the food and beverage industry, single screw pumps find applications in handling viscous liquids, shear-sensitive fluids, and delicate food products. From transferring chocolate, syrups, and sauces to dosing ingredients and conveying dairy products, these pumps offer hygienic and gentle product handling, maintaining the integrity and quality of the transported materials. Their sanitary design, ease of cleaning, and compliance with food safety standards make them indispensable in food processing and packaging facilities.

Chemical and Petrochemical Processing

Single screw pumps play a vital role in chemical and petrochemical processing plants for transferring various fluids, including acids, solvents, polymers, and specialty chemicals. Their ability to handle aggressive chemicals, high temperatures, and demanding operating conditions makes them suitable for a wide range of applications, such as chemical dosing, polymer metering, and transfer of corrosive liquids. With proper material selection and customization options, these pumps offer reliable and efficient performance in challenging chemical processing environments.

In conclusion, screw pumps find extensive applications across industries such as oil and gas, wastewater treatment, food and beverage, and chemical processing. With their robust construction, versatile capabilities, and ability to handle diverse fluids, these pumps contribute to enhancing process efficiency, reliability, and product quality in various industrial operations.

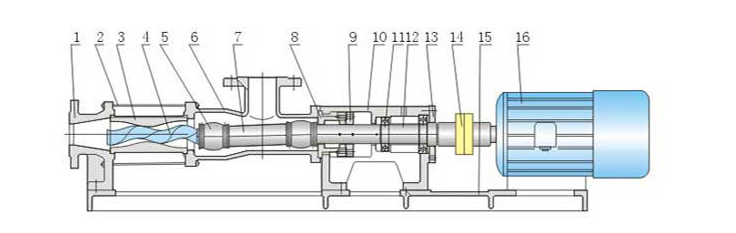

Mono Screw Pump section drawing

1. Discharge body

2. Pull rod

3. Stator

4. Screw shaft

5. Universal joint or pin joint

6. Inlet body

7. Coupling shaft

8. Packing seat

9. Packing gland

10. Bearing seat

11. Bearing

12. Drive shaft

13. Bearing cover

14. Coupling

15. Baseplate

16. Motor