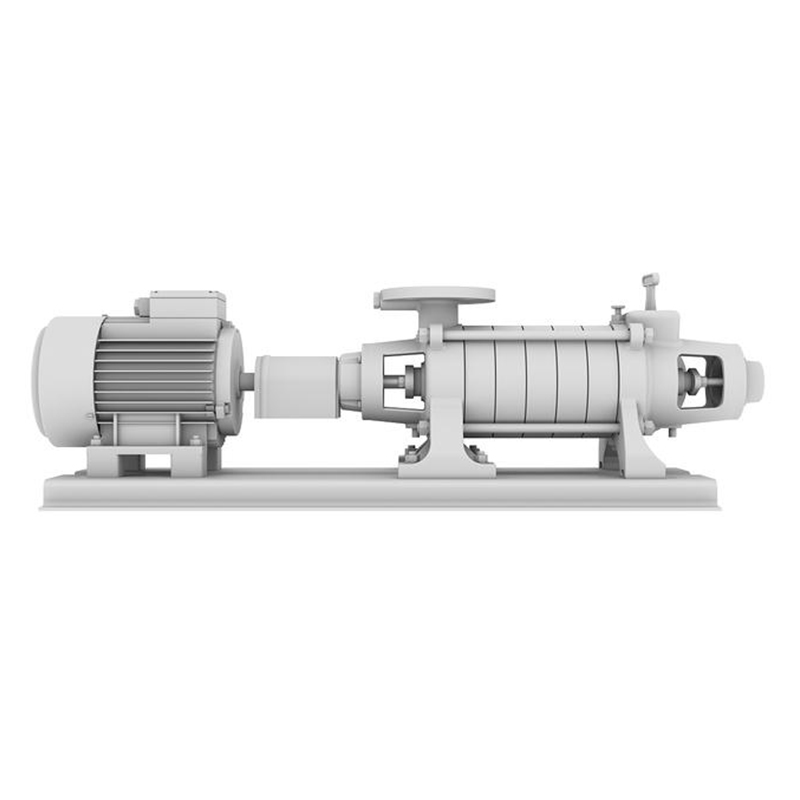

Progressive Cavity Pump

- Gaotian

- Shanghai

- 15days

- 1500

G series is progressive cavity screw pump(single screw pump. It belongs to the group of rotary positive displacement pumps. Progressive Cavity Pump is used in almost industry sectors for conveyance and dosing of various media. Preferably, media with or without solids having low to very high viscosities conveys. However, it is also suitable for conveying aggressive media, such as the ones used in paper making, waste water treatment or brewery.

·City sanitation: Activated sludge, Sewage, Cement milk, Concentrate scum, Mud, Digested sludge, Primary Sludge

· Ship: Sludge, Bilge, Chemical

· Food: Millet-jelly, Jam, Starch, Butter, Yeast, Ground meat, Ground ish, Fruit, Vegetable, Corned beef, Ketchup

· Paper and Cellulose: Pulp, Clay and Starch

· Chemical: Grease, Material of chemical fiber, Coating color, Pitch, Waste oil

· cosmetics: Cream, Tooth paste, Antibiotics, Glyceriniice1

· Paints: Pigment, Picture ingredient, Lacquer

· Steel manufacturing and ceramic industry: Grinding liquid, Clay, Blaster, Pit liquid waste

Progressive Cavity Pump description

The G type screw pump is a new type of pump that operates on the principle of volume engagement. Its main components are the eccentric screw (rotor) and the fixed liner (stator). Due to the special geometrical shapes of the components of the screw pump, separate sealed chambers are formed, allowing the medium to flow uniformly in the axial direction. This results in low internal flow velocity, constant volume, and stable pressure, thereby preventing vortex formation and agitation. The output pressure of each stage of the pump is 0.6 MPa, with a head of 60m (for clear water), and a self-priming height generally around 6m. It is suitable for conveying media with a temperature below 80°C (special requirements can be met up to 150°C).

The stator is made of various elastic materials, allowing the pump to transport high-viscosity fluids and media containing hard suspended particles or fibers, which general types of pumps cannot handle. Its flow rate is proportional to the speed.

The transmission can be direct through a coupling, or it can use a variable speed motor, V-belts, gears and other speed regulating devices.

This type of pump has few parts, a compact structure, small size, and is easy to maintain. The rotor and stator are the vulnerable parts of this pump, and their simple structure makes them easy to assemble and disassemble.

Progressive Cavity Pump details

The G-type single screw pump is a new type of pump that operates on the principle of volume engagement. Its main components are the eccentric screw (rotor) and the fixed liner (stator). Due to the special geometrical shapes of these components, separate sealed chambers are formed, allowing the medium to flow uniformly in the axial direction. This results in low internal flow velocity, constant volume, and stable pressure, thereby preventing vortex formation and agitation. The output pressure of each stage of the pump is 0.6 MPa, with a head of 60m (for clear water), and a self-priming height generally around 6m. It is suitable for conveying media with a temperature below 80°C (special requirements can be met up to 150°C). The stator is made of various elastic materials, allowing the pump to transport high-viscosity fluids and media containing hard suspended particles or fibers, which other types of pumps cannot handle. Its flow rate is proportional to the speed. Transmission can be direct through a coupling or using variable speed motors, V-belts, gearboxes, and other speed regulating devices. This pump has few parts, a compact structure, small size, and is easy to maintain. The rotor and stator are the vulnerable parts of this pump, with a simple structure making them easy to assemble and disassemble.

Media Transported:

- Liquids of various viscosities, especially those that are thick and difficult to transport

- Liquids of various concentrations and dehydrated dry materials

- Liquids containing solid particles, fibers, or suspended matter

- Mixtures of liquids, gases, and solids

- Sensitive liquids that cannot tolerate agitation, shearing, or scavenging

- Corrosive liquids

- Wide adaptability, capable of transporting all flowing media and even non-flowing materials

- Stable flow rate and pressure, without pulsation

- Changing the speed can adjust the output flow rate, making it suitable for metering and dosing

- Strong suction capacity, low operating noise, no leakage, and no temperature rise.

Media Transported: Liquids of various viscosities, especially those that are thick and difficult to transport. Liquids of various concentrations and dehydrated dry materials. Liquids containing solid particles, fibers, or suspended matter. Mixtures of liquids, gases, and solids. Sensitive liquids that cannot tolerate agitation, shearing, or scavenging. Corrosive liquids.

Operating Characteristics: Wide adaptability, capable of transporting all flowing media and even non-flowing materials. Stable flow rate and pressure, without pulsation. Changing the speed can adjust the output flow rate, making it suitable for metering and dosing. Strong suction capacity, low operating noise, no leakage, and no temperature rise.

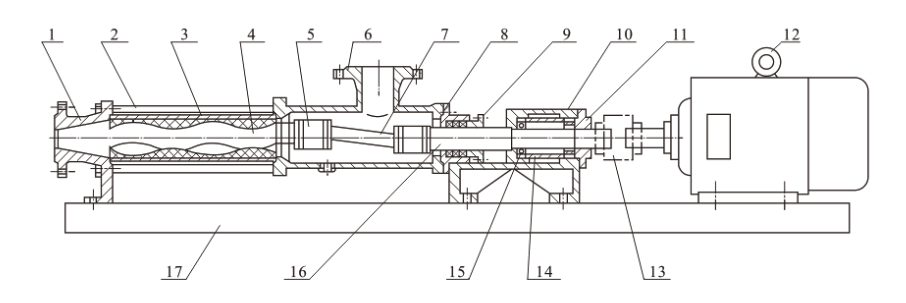

Progressive Cavity Pump section drawing

1Discharge cavity

2Pull-bar

3Screw sleeve

4 Screw axis

5 Directional nodeassembly

6 Suck-in pipe

7 Joint shaf!

8 Packing seat

9 Packing gland

10 Bearing seat

11 Bearing cover

12Motor

13 Cluteh

14 Muff

15 Bearing

16 Driving shaft

17 Foundation