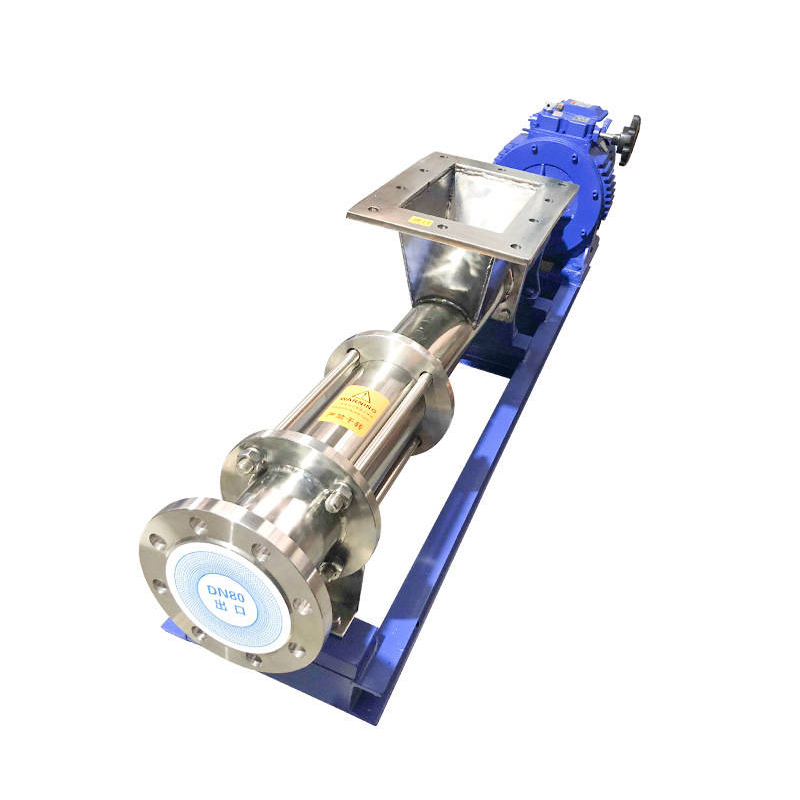

Positive Displacement Screw Pump

- Gaotian

- Shanghai

- 15days

- 1500

Characteristics of Positive Displacement Screw Pump

1. High reliability: Screw pumps have a simple structure and few moving parts, resulting in higher reliability due to fewer vulnerable components.

2. Long lifespan: The screw and liner of screw pumps are in solid contact, resulting in slow wear and a longer lifespan.

3. Stable flow rate: The flow rate of screw pumps is proportional to the rotational speed, resulting in a stable flow rate output.

4. Strong adaptability: Screw pumps can adapt to liquids of various viscosities and temperatures, and even liquids containing impurities and particles.

5. Low noise: Screw pumps operate with minimal vibration and smooth operation, resulting in low noise.

6. Easy maintenance: Screw pump components are easy to replace, making maintenance convenient and operation easy.

Positive Displacement Screw Pump Introduction

The screw pump is a type of positive displacement pump that relies on the rotary motion of the screw and liner to convey liquids. Its characteristics include simple structure, stable flow rate, minimal pressure pulsation, convenient flow rate and pressure adjustment, and low noise. It has been widely used in industries such as petroleum, chemical, pharmaceutical, papermaking, food, and environmental protection.

Classification of Positive Displacement Screw Pump

Screw pumps can be classified into single-screw pumps, twin-screw pumps, and triple-screw pumps based on the number of screws. Single-screw pumps have only one screw, twin-screw pumps have two screws, and triple-screw pumps have three screws. Their main differences lie in the characteristics of the conveyed medium, pressure, and flow range.

Working Principle of Positive Displacement Screw Pump

The working principle of screw pumps is that when the motor's rotary motion drives the screw to rotate, the engagement space between the screw and liner gradually increases, pushing the liquid from the suction end to the discharge end with higher discharge pressure. The liquid is uniformly pushed into the pipeline, resulting in stable discharge pressure and continuous flow.

Application Scope of Positive Displacement Screw Pump

Petrochemical Industry: Used for conveying various oils, chemical products, and additives.

Pharmaceutical Industry: Used for conveying drugs, raw materials, and intermediates.

Papermaking Industry: Used for conveying pulp, coatings, and chemicals.

Food Industry: Used for conveying various foods and beverages.

Environmental Protection Industry: Used for conveying sewage, waste oil, and exhaust gases, among other waste products.

Other Fields: Used for conveying various viscous and corrosive media, such as grease, paint, and coatings.

Precautions for Using Screw Pumps

During installation, it is essential to keep the pump horizontal to avoid affecting its performance and service life.

Before starting, ensure that the pipelines and inlet and outlet valves are clean and free of obstructions.

After shutdown, flush the liquid from the inlet and outlet pipelines to prevent residual liquid from solidifying or corroding the equipment.

When transporting flammable and explosive media, use nitrogen or other inert gases instead of air for sealing.

During pump operation, pay attention to the smoothness of the sound and check for abnormal vibrations and friction. If any issues arise, stop the pump immediately for inspection and troubleshooting.

Regularly inspect the pump's bearings, shaft seals, and packing to ensure their normal operation and service life.

After long-term shutdown, conduct a comprehensive inspection and maintenance of the pump to ensure its normal operation and service life.

When replacing bearings, shaft seals, and other components, pay attention to matching the models and specifications to ensure correct installation and effectiveness.

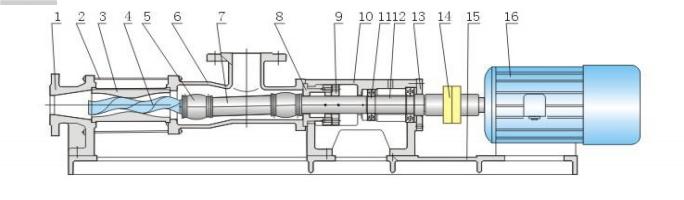

Positive Displacement Screw Pump section drawing

1. Inlet

2. Pull rod

3. Stator

4. Screw shaft

5. Universal joint pin connection

6. Outlet

7. Connecting shaft

8. Packing seat

9. Packing gland

10. Bearing seat

11. Bearing

12. Drive shaft

13. Bearing cover

14. Coupling

15. Baseplate

16. Motor

Close-up Photographs Of Screw Pumps