Stainless Steel Industrial Pulp Pump

- Gaotian

- Shanghai

- 15days

- 1500

1. Efficient and Energy-saving;

2. Excellent Cavitation Performance and Long Service Life;

3. High Concentration Capability and Non-clogging;

4. Reasonable Structure and Convenient Maintenance.

Industries where Stainless Steel Industrial Pulp Pump is applicable include:

• Papermaking Industry: Used for the circulation, lifting, and pressurization of media with a concentration below 6% in pulp conveying and alkali recovery industrial processes.

• Sugar Industry: Utilized for conveying syrup with a concentration below 4% and a viscosity below 150mm2/s.

• Urban Sewage Industry: Employed for the circulation, lifting, and pressurization of media in wastewater treatment processes.

The Stainless Steel Industrial Pulp Pump is also primarily used in the following industries

1. Papermaking Industry: It is used for the circulation, lifting, and pressurization of media with a concentration below 6% in pulp conveying and alkali recovery industrial processes.

2. Sugar Industry: It is used for conveying syrup with a concentration below 4% and a viscosity below 150mm2/s.

3. Urban Sewage Industry: It is used for the circulation, lifting, and pressurization of media in wastewater treatment processes.

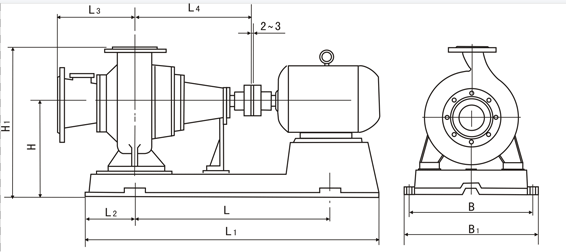

Stainless Steel Industrial Pulp Pump structure introduction

1. The stainless steel pulp pump is a single-stage, single-suction, cantilever type structure, mainly composed of pump body, impeller, pump cover, wear plate, and suspension components.

When viewed from the motor end, the motor rotates clockwise, and the pump has axial suction and radial (middle) discharge.

The pump has a back-opening structure, so the inlet and outlet pipes do not need to be disassembled during maintenance.

The pump shaft is supported by two high-precision rolling bearings, and uses thin oil lubrication (20# machine oil).

The shaft seal can be in the form of mechanical seal or packing.

The clearance between the wear plate and the front side of the impeller can be adjusted by adjusting the screw.

The pump and motor are directly connected by a pin coupling.

Stainless Steel Industrial Pulp Pump section drawing