Progressive Cavity Screw Pump

- Gaotian

- Shanghai

- 15days

- 1500

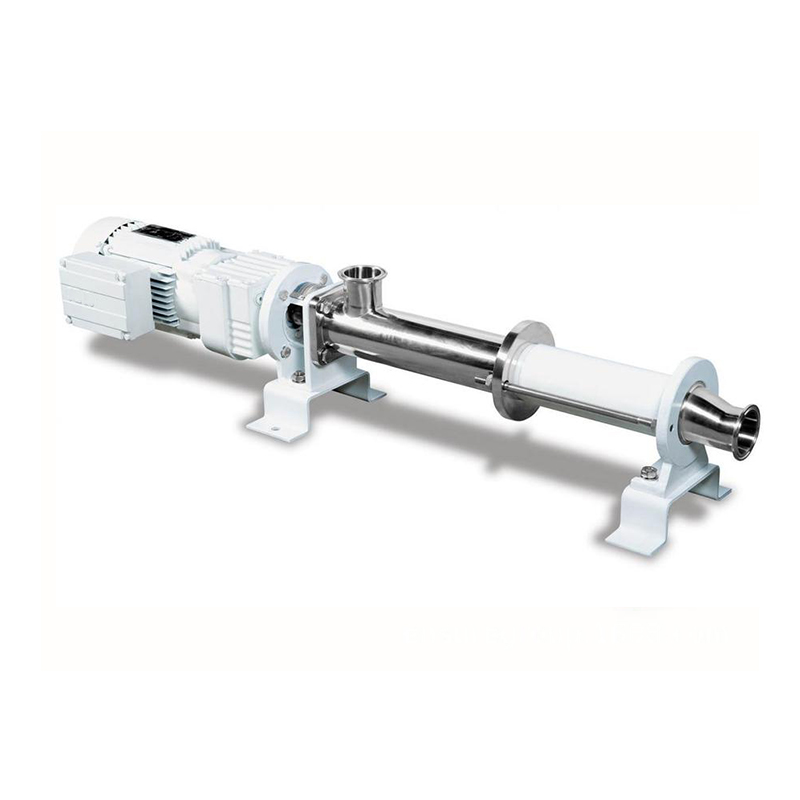

The Progressive Cavity Screw Pump was first developed and successfully applied in Peru in the 1960s, initially used for catching fish and shrimp. In order to prevent solid substances from clogging and ensure smooth outflow, a twisted screw blade is installed in the impeller. Along the axial extension of the conical wheel hub from the suction port, the radius of the flow channel gradually increases, forming a helical flow passage. Building on the original design, advanced production techniques from leading enterprises were introduced to further improve the pump. In addition to the original belt pulley transmission method, a new shaft-coupled transmission method was developed, expanding the pump's application range. After years of market promotion, it has been widely used in industries such as papermaking, fishing, sewage treatment, gelatin processing, food processing, and chemical engineering.

Progressive Cavity Screw Pump description

The Progressive Cavity Screw Pump is an efficient, reliable, and versatile positive displacement pump with numerous advantages suitable for various industrial and commercial applications. Here are the typical advantages of the Progressive Cavity Screw Pump:

1. High Efficiency: The Progressive Cavity Screw Pump delivers uniform and stable flow rates, capable of handling high viscosity, high solids content, and crystallization-prone fluids, thereby improving production efficiency.

2. Self-Priming Ability: Due to its unique design, the Progressive Cavity Screw Pump possesses strong self-priming capabilities, capable of handling various fluids, including those with gas and solid particle content.

3. Low Pulsation: The Progressive Cavity Screw Pump provides smooth fluid conveyance, reducing pulsations and vibrations within the system, contributing to enhanced stability and accuracy in fluid transfer.

4. Versatility: It is adaptable to a wide range of media, including liquids, semi-solids, and high-viscosity fluids, suitable for diverse industrial sectors such as chemical, food processing, paper, and wastewater treatment.

5. Low Shear: Operating the Progressive Cavity Screw Pump does not generate excessive shear forces, helping to maintain the stability and properties of the medium, particularly suitable for applications with stringent requirements for the medium.

6. Low Noise: Compared to other types of pumps, the Progressive Cavity Screw Pump operates with relatively low noise levels, contributing to an improved working environment.

7. Reversible Conveyance: The Progressive Cavity Screw Pump features reversible conveyance, making it suitable for applications requiring bidirectional fluid transfer.

In summary, the Progressive Cavity Screw Pump, with its efficiency, versatility, and stable performance, has become the ideal choice for fluid conveyance in industrial settings, providing reliable solutions for various applications.

Applications of Progressive Cavity Screw Pump

Petroleum Industry: Extraction and transportation of crude oil, heavy oil, gas, sand mixtures in oil fields.

Chemical Industry: Conveying synthetic fiber liquids, viscous glue liquids, inks, nylon powder liquids, suspensions, emulsions, polymers, coagulants, precipitants, and lime milk.

Paper Industry: Conveying low-consistency pulp, cotton pulp, straw pulp, various coatings, white liquor, black liquor, and heavy oil in alkali recovery at different concentrations.

Non-metallic Mines: Conveying suspensions, ceramic oil, refractory clay suspensions in the ceramic industry. Conveying raw material pulps in the high-collared production.

Food Industry: Conveying food materials, sauces, dairy products, fruit juice, jams, carbonated drinks, and seasonings. Conveying various liquids such as diatomaceous earth, malt mash, yeast, filter mud in breweries.

Other Industries: Transportation of fuel, sweeping, removal of offshore oil, discharge of sewage, and oily water to the shore, as well as loading and unloading various materials in ships. Transportation of mortar, plaster, and paint in the construction industry. Sludge transportation in the environmental protection industry.

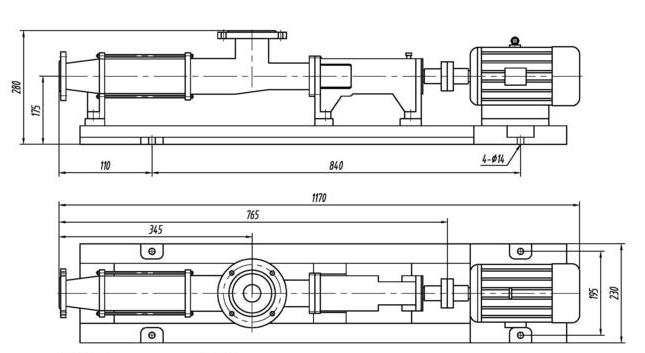

Progressive Cavity Screw Pump section drawing