Centrifugal pump

Gaotian is a specialized manufacturer of Centrifugal pumps, offering a comprehensive range of standard and non-standard Centrifugal pump worldwide. From our extensive collection, we provide both standard centrifugal pumps and custom-designed units, including cast iron pumps for durability and corrosion-resistant stainless steel centrifugal pumps for harsh environments. With a focus on global supply, Gaotian-pump ensures reliable and tailored solutions for various industries and applications.

-

Hot Cooking Oil Pump

Hot Cooking Oil Pump is an axial high temperature medium transfer circulation vortex pump, the transfer circulation medium is not containing particles, fibers of liquid (water, ethylene glycol, hydrocarbon solution, thermal oil, etc.). Product flow medium, all use SUS304 stainless steel material, with self-priming, low noise, high efficiency, easy installation, high temperature resistance and other characteristics.

Email Details -

Thermal Fluid Pump

Thermal Fluid Pump is widely used in petrochemical, oil, construction equipment, asphalt mixing station, food, pharmaceutical, rubber, textile printing and dyeing, synthetic fiber, building decoration and other industrial sectors of thermal oil circulation heating system.

Email Details

The pump has low noise and vibration, stable operation, and can run continuously without trouble for a long time. With good thermal adaptability, sealed, no leakage. -

Heat Conductive Hot Oil Pumps

Heat Conductive Hot Oil Pump is a single-stage cantilever structure divided into foot support and center support, the pump inlet is axial suction, and the outlet is vertical upward. The hot oil pump and the drive motor are mounted on the same base through the elastic coupling, and the whole unit does not need to add cooling system.

Email Details

Heat conduction oil pump is mainly composed of shell, rotor, bearing, seal and other parts, using packing seal structure, additional temperature resistant oil seal, auxiliary sealing function, pump and motor with three claw type elastic coupling. The high temperature heat conduction pump changes the structure of the traditional heat pump from the design, adopts the cooling method of natural heat dissipation, reduces the volume of the pump, makes the structure simple, saves operating costs, and is strong. -

Self Priming Centrifugal Oil Pump

Self-priming centrifugal oil pump, used for transporting petroleum products such as gasoline, diesel, kerosene, aviation fuel, etc., is an excellent cargo oil pump and suitable for the transportation of oil in land oil depots and oil tankers. It can also be used to transport seawater, fresh water, etc. After changing to use corrosion-resistant mechanical seals, it can transport chemical liquids.

Email Details -

End Suction Pump

End Suction Pump Body Structure: The end-suction pump is composed of a pump body, impeller, shaft, sealing device, and other components. Inside the pump body, there is a suction pipe and a discharge pipe, which are connected to the external system through these two pipes.

Email Details

End Suction Pump Impeller Rotation: When the pump's electric motor is started, the impeller on the shaft also begins to rotate. The impeller, under the action of centrifugal force, causes the liquid to be drawn into the pump body and then flung into the discharge pipe. -

Self Priming Trash Pump

Self Priming Trash Pump is designed for the treatment of municipal and industrial sewage, as well as for stage treatment and concentrated treatment systems for various sewage applications. It has earned the title of the "King of Self-Priming Sewage Pump" and is recognized as the most ideal new-generation sewage product on the market.

Email Details -

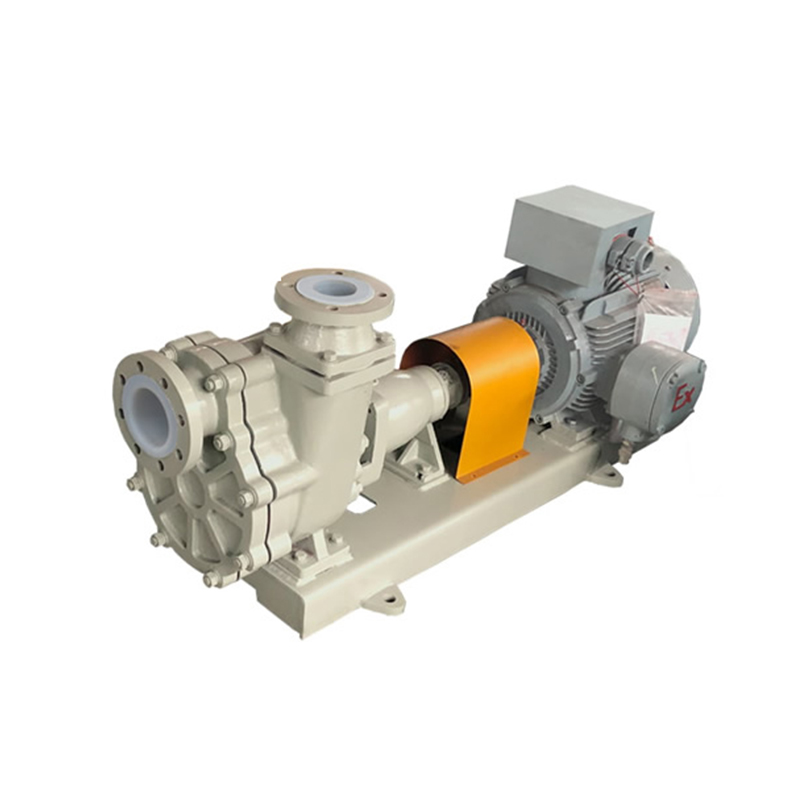

Plastic Lining Acid Transfer Pump

Plastic Lining Acid Transfer Pump is designed and manufactured according to standards and combining non-metallic pump processing technology. Plastic Lining Acid Transfer Pump body is made of a metal shell lined with polytetrafluoroethylene (F46), and the pump cover, impeller, and shaft sleeve are all made of metal inserts wrapped in fluoroplastics and sintered and molded. The shaft seal uses a Teflon-filled material, and the inlet and outlet are both reinforced with cast steel bodies. The shaft seal uses an externally mounted four-oxygen corrugated pipe mechanical seal, which has multiple layers of protection and extends the service life of the mechanical seal. For dry conveying media with impurity particles, a non-cooling water single end face hard-to-hard (silicon carbide to silicon carbide) mechanical seal can be used, so users need to consider the solid content in the medium when selecting the model.

Email Details -

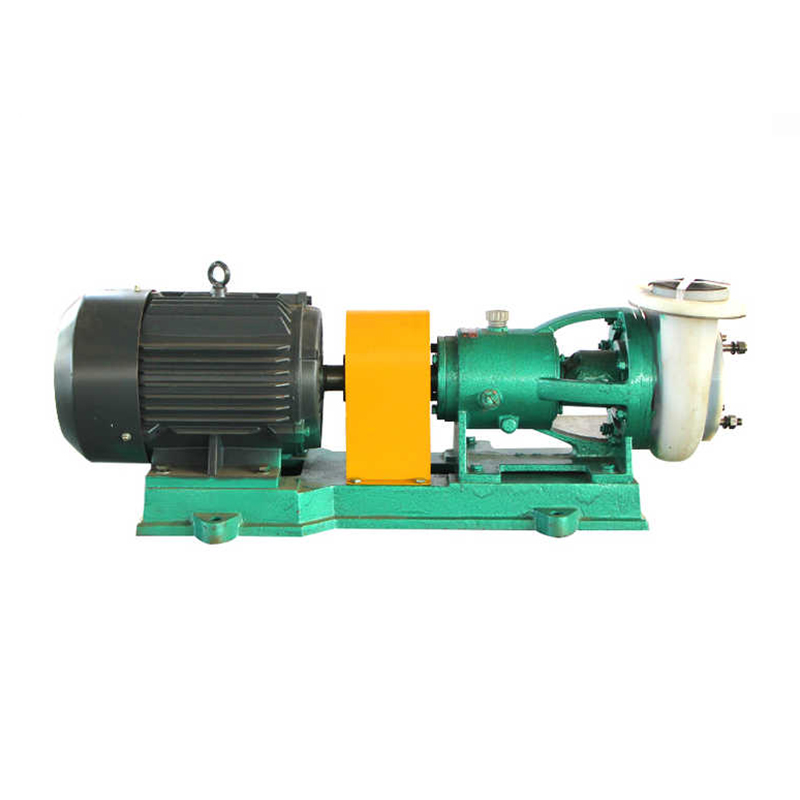

Fluoro Plastic Acid Proof Centrifugal Chemical Pump

The Fluoro Plastic Acid Proof Centrifugal Chemical Pump is a type of horizontal centrifugal pump that is highly resistant to strong corrosion. The pump body is made of a metal shell lined with polyvinylidene fluoride (F46). The pump cover, impeller, and shaft sleeve are all made of metal inserts wrapped in fluoroplastic and then sintered and molded. The shaft seal uses an externally mounted bellows mechanical seal, with the stationary ring made of 99% alumina ceramic or silicon nitride, and the moving ring made of PTFE filler material, ensuring resistance to corrosion and wear, making it one of the strongest corrosion-resistant equipment currently available. Its advantages include a compact and reasonable structure, high resistance to strong corrosion, reliable sealing performance, low noise, high mechanical strength, non-aging, convenient maintenance, smooth flow path, high efficiency, and energy savings.

Plastic Lined Pump Acid-resistant fluoroplastic centrifugal pump Fluoroplastic corrosion-resistant centrifugal chemical pumpEmail Details -

Heavy Duty Fluoroplastic Magnetic Pump

Fluoroplastic Magnetic PumpTechnical features:

Email Details

Full flow: 32~1240 L/min Flow can be selected according to operational requirements

Total head: 3.8~35M Meets various operational head requirements, providing more stable transfer of liquid materials

Fluoroplastic Magnetic Pump Main materials: PVDF, CFRETFE. Different fluoroplastics are provided based on the characteristics of the conveyed medium Suitable temperature range: -20~90°C (PVDF), -30~110°C (CFRETFE)

Heavy Duty Fluoroplastic Magnetic Pump Application areas: Electroplating industry, new energy industry, semiconductor industry, photovoltaic industry, LCD glass panel, environmental protection industry

Heavy Duty Fluoroplastic Magnetic Pump Product features: Highly corrosion-resistant; Uses neodymium iron boron high-efficiency permanent magnet that does not demagnetize; Patented leak-proof integrated inlet and outlet; Wide variety, high flow, low noise; Lifespan of over 10 years